[WARNING: Technical content, which is then followed by pretty pictures]

I'm a gadget freak, and I tend to gravitate towards the gadgets that take up electricity. I can instantly think of dozens of electrical devices that I'd like to put in my beetle: radios, navigation gadgets, instruments, defrost blowers, lights, you name it. All of those things require power to work, and the 30 amp generator that came with the car in 1972 just isn't going to support too much extra load.

The solution is to install an alternator. They produce more electrical power, at lower engine RPM even. In the process of reading about alternators, I've become facinated with that technology. The automotive alternator, like a slingshot orbital maneuver, is one of those very rare cases where nature lets you have it both ways, seemingly defying physics. (The role of a generator or alternator is the same; the engine turns them and using the energy of rotation, they product direct-current electricity to power the electrical systems of the car.)

The principle of a generator is very simple and intuitive. A uniform magnetic field is created by coils of wire and soft iron cores, called "pole pieces". A bunch of coils of wire are rotated in the magnetic field. The coils cutting through the magnetic field create voltage in the coils which drives current. Now a single wire loop rotated in a magnetic field would product a sine wave AC current, so the rotating part of the generator is made up of a whole bunch of coils at different orientations. Brushes and contacts (together called a commutator) connect the one coil that's cutting through the field the most together with the generator output wires, so you get a more or less steady voltage out. The voltage of the generator is regulated by adjusting how much current is in the magnet coils (called field coils).

By the way, an interesting fact about generators is that if you apply electric current to what is normally the generator output, the generator will run like a motor.

Generators tend to be heavy because to increase their output, the rotating coils must be made of heavier wire, and the pole pieces tend to be heavy as well. The current to the field wires is supplied from the generator's output. The magnetic pole pieces retain some magnetism even when the generator isn't operating, so a generator is self-exciting; it can produce current if the rotor is spun from the outside.

An alternator is a slick way to do the same job that the generator does, more efficiently, but to create alternators it required good semiconductors. The general principle is the same, a coil of wire moving within a magnetic field produces a voltage in the wire. However, in an alternator, it's the magnetic field that moves and the coils stay still. The center part of a an alternator, called the "rotor", is two halves sandwiched together with coils in between the halves so that as it turns, each coil of wire in the outer portion of the alternator gets rapidly alternating magnetic fields. These coils are called the "stator". (There are good photos of a rotor and stator here, and a little farther down is an electrical schematic of the alternator.)

The engine of the car turns the rotor, and as the rapidly varying magnetic fields continually pass by the coils in the stator, they cause current to "slosh" back and forth. This sloshing would produce current that flowed in both directions (AC, or alternating current) except that the stator coils are then connected to a series of diodes set up as rectifier, which are arranged such that current can only flow out in one direction. There are typically three separate sets of coils and each one has a diode going in each direction so that each "push" from the magnetic field moves current out of the alternator in the correct direction, so none of the energy is lost.

Some of the current from each coil is tapped to provide current to the rotor magnet coils. The amount of current is controlled by the alternator "regulator", which adjusts the current to make the alternator output voltage as close as possible to a pre-determined value, typically 14.4V in a car. The alternator spinning produces output current which produces current in the magnet which produces current...which almost sounds like perpetual motion. It is a positive feedback system, except there is an external source of energy, the rotor which is being forcibly spun by the engine.

Interestingly, one disadvantage of an alternator is that the way the rotor is made, the alternator doesn't have any residual magnetism, so if you spin an alternator without an external source of current, there's no field coil to start generating output current. The way typical alternators work is when the ignition key is turned on, battery voltage is applied to the alternator warning light. The other side of the alternator light is connected to the positive side of the field coil in the alternator. (This can be clearly seen here, in a diagram on Speedy Jim's VW web site.) Since the field coils are essentially a short circuit at this point, the alternator light lights up this is when you turn the key to "on" but before you start the engine. The light lighting up pushes a small amount of current through the field coils in the rotor. When the engine starts, the (now energized) rotor spins, pushing current through the stator coils, producing voltage at the alternator output, which pushes more current through the rotor, which produces more current in the stator coils, et cetera. This continues until the voltage at D+ is at the same voltage as the battery, which means the alternator is now producing all the field current it needs. This also has the effect of making the alternator light go out, since B+ and D+ (the points on either side of the alternator light) are at the same voltage.

The story so far: Current through the alternator light provies a small start-up current to the rotor. The spinnning of the engine provides energy which initiates a positive feedback loop that raises the voltage in the alternator to a pre-determined level, after which the regulator starts limiting the rotor current to keep the output voltage at exactly that level.

On problem with this system is that while the alternator light will detect a catastrophic failure of the alternator, it won't necessarily detect that the alternator is producing not quite enough current to run the engine. This happened to me once, I was driving along fine and the first thing I noticed was the tachometer stopped working. Because of this problem with the warning light, that was, of course, after the battery was run most of the way down.

Now, back to the beetle. The generator (or alternator) in the beetle is driven by a pulley attached to the crankshaft, and at its other end drives the main engine cooling fan. Here's a by beetle's engine partially taken apart:

The top pulley of the belt is on the generator. The other end of the generator goes into the fan shroud where it drives the cooling fan.

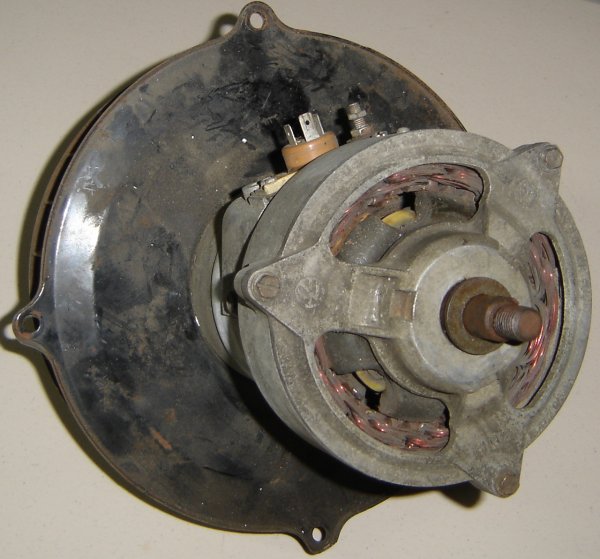

To increase electrical output, in 1974 the volkswagen beetle went to an alternator rather than a generator for all of these reasons. To increase the electrical capacity of my car, I will be installing one at some point. To get some of the parts, not necessarily to buy an alternator to use, I bought a beetle alternator on ebay, shown here with the cooling fan but without the pulley:

You'll notice that unlike the generator shown above, the alternator is fatter at the pulley end than the generator is. The support pedestal for the alternator must provide space for this, and the carburetor and the fuel pump must provide for this extra required size.

You can sort of see the parts of the alternator here. Looking in the holes at the end of the alternator, around the edge you can see the copper-colored stator coils. Just inside of that is the rotor.

The alternator I have appears to not have a regulator installed:

I guess this is an externally regulated alternator? Or perhaps one where the regulator has been removed?

As far as buying an alternator to use, I probably will buy one new. California Import Parts has some nice alternators with install kits, including some 75 amp ones (all the late 1970s beetles came with a 55 amp alternator as stock. However, in the process of researching this post, I came across a company selling a 95-amp beetle alternator. Maybe a birthday present?