Site Navigation:

Archives:- May 2018

- November 2017

- September 2017

- May 2017

- February 2017

- January 2017

- December 2016

- August 2016

- March 2016

- February 2016

- December 2015

- October 2015

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

I talked in this post about wanting to get a Hyundia Accent as my next car. I still liked the VW (New) Beetle fine, but I haven't been really excited about it in years. The air bag light came on and stayed on recently. And I had a couple of stressful days about things that I couldn't do anything about. So I decided that was the day to go swap out cars. I searched for a Hyundai Accent with cruise control, and came up with one. So we went and bought it and swapped cars out.

Here's the last Beetle odometer reading when we traded it in at the

dealer:

and the new(er) Accent at startup:

And parked at our house:

It has a real live key to start, and the only genuine "ACC" position

on a key cylinder that I've seen in a modern car in a very long time!

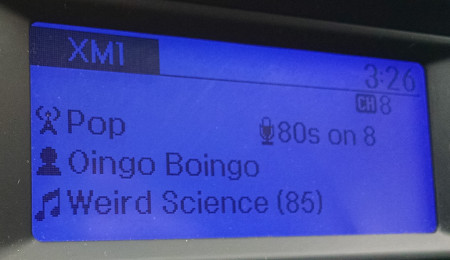

It has a built-in satellite radio, which I got configured on

Saturday:

which is nice in that there's many fewer wires around than I had in

the beetle.

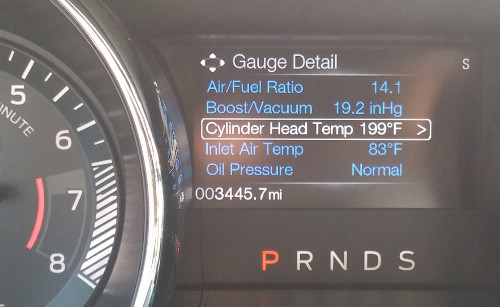

Here's my view driving. I do still have the power wire for the dash

GPS navigator.

I worked on a couple other infrastructure problems this week. I've

had a ink stamp that I've used for putting our return address on

things since we moved here. I got a new ink pad recently, but I also

needed to replace a couple of the characters. I do that, and I also

wanted to create a place to hang up the stanp. I decided to do that,

and then 15 minutes later, I had one made out of double-headed nails

and a piece of scrap wood:

which now sits at the desk where I pay bills.

And I'm going to try to carve out the time to put the vintage Beetle

back together and get it running. On Monday I used over cleaner to

clean some of the carbon off the cylinder heads:

(I forgot to take an "after" photo.)

And I've been getting all the engine pieces together in the garage.

Here is Pangur, inspecting my work:

In the foreground you can see the freshly reground crankshaft and the

new camshaft. In the background, engine mount sets, seals, hardware,

and way at the back the clutch.

One thing I accomplished this year on the house was replacin the horrid bronze sink in our downstairs half-bath with one that doens't require polishing. Bronze is fine--if you have servants who can polish it every day. Otherwise it's green and yucky all the time. So my mother-in-law and my wife bought a new sink with a new pedestal at the end of the summer when we were back in town. I took a lot of a weekend later in the fall and installed the sink in the half bath.

Here's Pangur inspecting the sink in the garage.

The faucet that my son picked out for the sink. I was thinking a

metallic bronze faucet, but he like the shiny one. Here I'm checking

to make sure that the hoses I got are the right ones.

The under-sink drain attachments that we're going to have to transfer

over to the new sink.

The new sink on its pedestal, with the old sink basin sitting next to

it.

Old sink cabinet, with the basin removed, trying to get the cabinet

out.

Cabinet out.

Getting the new cabinet into the bathroom was a near thing. It had

this much room to get past the door frame (that's with the door

removed from the hinges).

New cabinet in, getting the plumbing hooked up.

Getting the drain components set up and set for length.

Sink pieces in living room getting all the pieces put together.

Drain stopper control hooked up.

The sink has a built-in edge that overlaps the counter all around. I

realized that if I put the cabinet right up against the wall, the sink

won't fit down in it. I had to put 1/2-inch spacers on the back and

side walls to move the cabinet out from the walls so that the sink

would fit. Here I'm nailing/gluing the spacers to the side of the

cabinet.

Sink in, ready to connect all the plumbing.

Drain plumbing all connected. Everything fits!

All finished! We have a nice, new, shiny sink in the half-bath.

Huzzah! Capital improvements FTW!

At some point my 2008 VW, which has been my trusty steed for over 8 years

and 145,000 miles, is going to fall out from under me and won't be

worth keeping. I do a lot of my pre-car shopping from rentals. I've

liked Hyundais for years, but due to a rental I had recently when I

was getting my airplane back from annual, the Hyundai Accent is now at

the top of my list.

For one thing, it's just a pretty car, especially the white ones.

I have to say, I really like the combination of the big analog gauges

at the sides for rpm and speed, and the digital strip gauges for temp

and fuel at the top.

I like the gear shift setup and the feel and the action of the gear

shift. And it has manual shifting when you want it. It doesn't have

the sport shift that my VW does, but I'm not sure how much I'd miss

that.

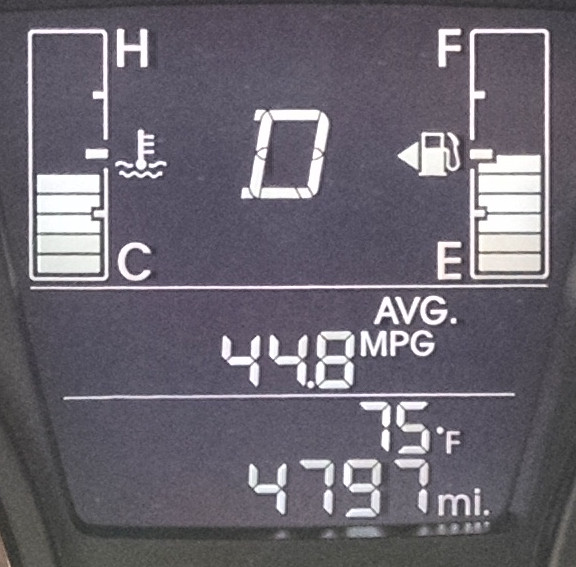

It got over 44 miles per gallon during the time I was driving it,

which is crazy-good for a gasoline car.

And it was nice to drive. One annoying thing was the rental didn't have cruise control. I know they come with them, so I'd want to be sure to get that or have it added. (This is a blog post that's as much a reminder to myself as anything.)

So. This blog is mostly about computers and airplanes and cars and tech stuff, but now for a series of posts about the human side of the house. My wife and I started the process to adopt a kid from China in early 2015. We flew to China in May 2016, finalized the adoption and Visa paperwork (that whole process is a series of posts in itself), and flew home with him two weeks later, and he's been our son for about one year.

I may talk about the process of adoption at some point. In this post I want to put down something that I've been holding in my long-term memory since we took the trip. In brief, we flew over on a Thursday through Friday to Beijing. Saturday we touristed around, partially to get our internal clocks on China time, then slept one more night in Beijing. On Sunday we took a bullet train to Jinan to meet up with our son (again, we'd hosted him in the US the previous year). We finalized the adoption Monday, touristed around Jinan a couple of days. Then we flew to Guanzhou (near Hong Kong) and stayed there for almost a week until we could have our appointment at he US Consulate to get his entrance Visa to the US the following Monday. Then that Wednesday we flew home.

The shortest stay we had was in Beijing, and we were super-jet-lagged. We had so little time in the hotel in Beijing, and in this room, that I don't have that many photos. I did manage to get some of the light switches, which I found very interesting, and I want to discuss here. My records indicate that the hotel we stayed in in Beijing is the "Novotel Beijing Sanyuan".

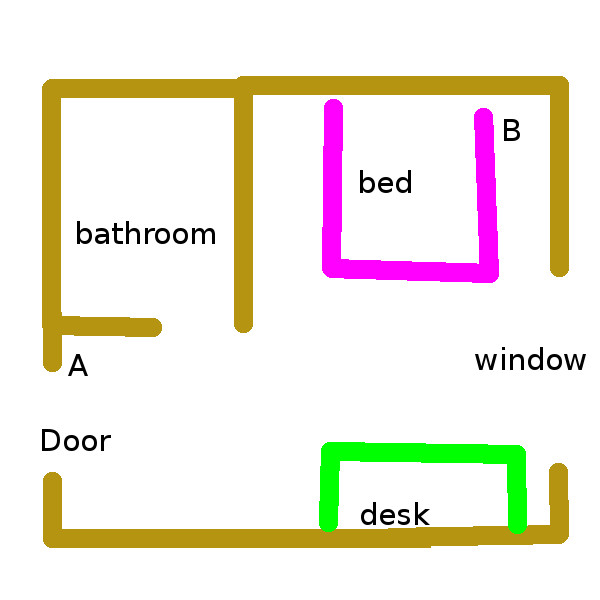

Here's a rough diagram of the room, from memory.

As is characteristic of hotel rooms in China (and I've more recently

been told, other places in the world too) There's a sensor near the

door (rougly in position "A" in the room diagram above, at shoulder

level) that turns on the electricity in the room when you insert a

card (presumably your hotel door key card). Here's a photo, with the

light switch for the light right by the door:

When you insert your key card, the electrica power in the rest of the

room turns on:

My hand for scale here. The light switches are the big chunky grey

things, as below the card sensor. The light that illuminated this

area was the one thing not controlled by the card sensor (maybe; I

don't remember that part well).

Here's the desk, with a couple of outlets above it:

The outlets and phone jacks, a little bit closer:

Which included an outlet right next to the phone that was the one

thing in the room that was always on, so I used that to charge our

laptop:

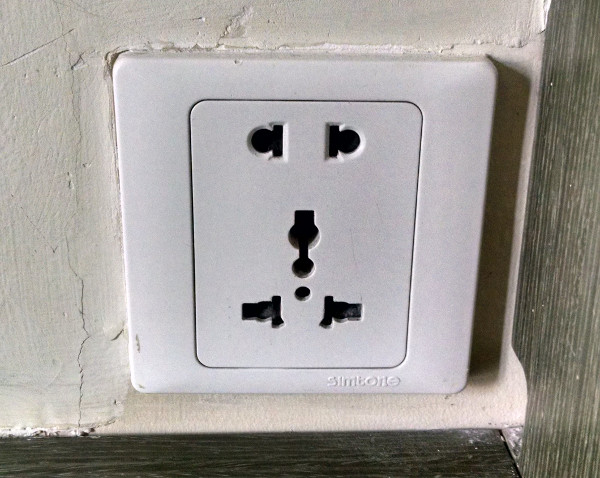

There were a fair number of receptacles in the room. This one is to the

right of the desk on a little shelf (for charging appliances, I

suppose). This one is fairly typical for receptacles for non-China

devices. All the various pin patterns are there, including US, UK,

European, Austrailian. I'm not sure a South African plug would work.

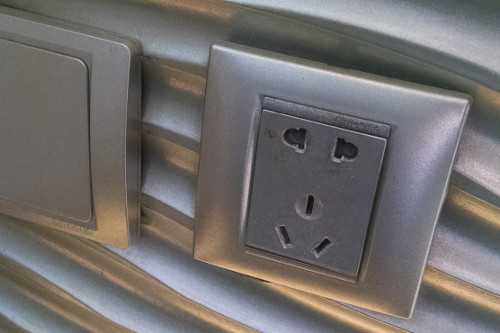

Here's a China-style receptacle. The bottom is the Chinese plug, the

upper one fits a two-pin European one or an American/Japanese plug.

Then there's a triple-switch by the bathroom that controls the lights

in and around it:

This is what drove me crazy about the room until I figured it out.

Here is the group of switches next to the right (standing at the foot

of the bed) side of the bed.

The top one is the "master" switch,

which feeds all the others in the room (except the 24-hour outlet, I

guess). It took us quite a while to figure out how this worked. It's

clearly labelled, as you can see, but there's a delay when putting the

card in the sensor by the door, and there may have been a delay

when you turned on the master until everything turned on. Due to the

delays, it took us a while to figure out the right combination so that

everything would in fact turn on. We finally got it, but it was

frustrating.

I loved the feel of the switches. They're big and chunky and had a nice heavy click to them.

I posted a video on youtube walking around the room. I also took a video of the timing of the card sensor turning the lights on and off.

So this was our hotel room in Beijing in China in May of 2016, and its interesting switches and its minor electrical mystery. I'm sure I'll talk more about this trip in a future post.

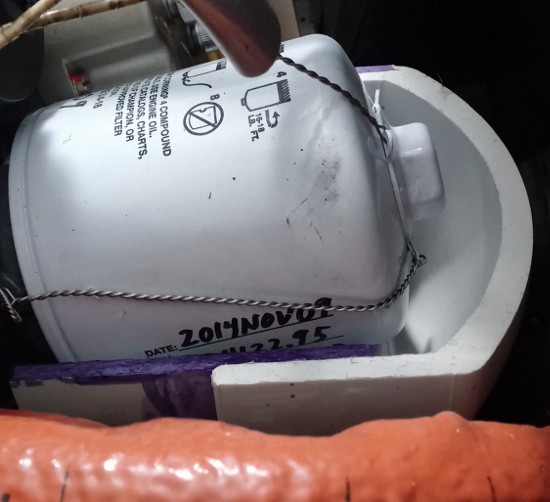

Sleeping overnight in Meridian, Mississippi on the way back home, I was figuring the trip was going pretty well. I'd been delayed by half a day by weather, but that was vastly better than several of my colleagues. So I headed to the airport first thing Monday morning to fly the last leg home.

.....aaaaaand there was no response from the electrical fuel pump.

It's not NECESSARY to fly the plane, or even to start it, but it IS

the backup in case the engine-driven fuel pump fails. So I had it

towed to the local repair place:

Here's the culprit, ready to be shipped off as an exchange for an

overhauled pump:

The shop on the field was mostly a turbine-airplane place, but I was able to help a mechanic get the proper access panel off and get him to the electric fuel pump. I then arranged to overnight the bad pump to the people with spares, and my wonderful wife (thanks darling!) shipped a check to the repair place (they don't take credit cards). Then I rented a car a drove back home, and left the plane there to be fixed once they got the pump back.

I ended up renting a Hyundai of some sort. I felt it was good omen

when songs like this kept coming on the satellite radio:

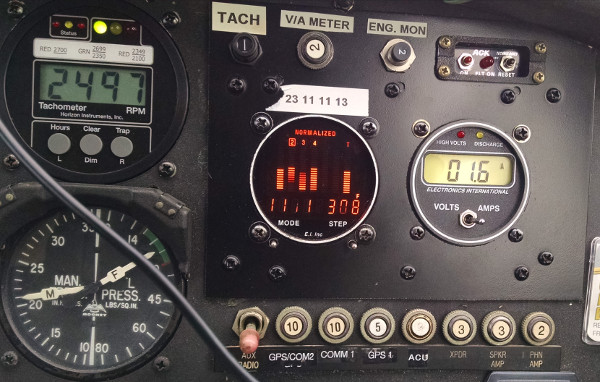

Obligatory instrument panel photo (pretty efficient car):

And a nice underpass on the way home.

I did get the airplane back eventually. But first, other house stuff.

Back in Austin, the plan was to fly my plane to Kerrville to the

Mooney fly-in, so that I could, finally, have my plan parked on the

field in front of the Mooney factory. The weather was crappy enough

that I decided to leave it tied down in Austin

and rent a car and drive to Austin instead.

My vague memory of the original planned sequence was this. I flew commercial from Oregon to Austin Friday morning. I got into Austin mid-afternoon Friday. I had planned then to fly my airplane to Kerrville and stay Friday and Saturday nights, and then fly all the way home on Sunday.

(My vague recollection is): The weather was bad in Austin when I got there, so I decided to wait to Saturday morning to fly. I was so tired I mostly went to bed. Saturday morning, the weather was slightly better but I'd have to be doing an instrument approach into crappy weather into Kerrville, so I decided not to. I rented a car to drive to Kerrville and back. (A lot of this is because I was giving a talk on electronic flight bag solutions that I hadn't finished yet. I'm a really really bad procrastinator sometimes.)

I rented the car in a huge hurry Saturday morning because I had to get on the road. I drove to the hotel in Kerrville and then sat in my hotel room for an hour finishing my talk. I gave the talk, that was fine, and then that evening was the banquet, which I stayed for the food and about the first half of the entertainment part. Since I was leaving so early the next morning, I ditched out of the rest of the evening.

I left super-early Sunday morning, like 4am. My plan was to race the thunderstorms that were coming in to Austin and try to get off the ground going east before they hit. It was interesting to drive with thunderstorms right behind you in the dark on roads you don't know. I got to Austin, and before I could get out of the rental car, it was bucketing down rain.

The car was GREAT to drive; I found out later one of the reasons it

accelerated so smoothly is that it has a continuously-varable

transmission. What with all the hurrying, I never got a photo of the

outside of it. I just have these three instrument panel shots. I

managed to figure out from screenshots that this is a Nissan Maxima.

Very nice car.

Mooney was prototyping a plane that they're going to be selling. A

small two-seater. Here's a couple of shots inside.

Note the single-level engine control in the center console. All

glass-panel; I think that's a Garmin 500? And with an iPad mount

already built-in. And USB power jacks in the center console:

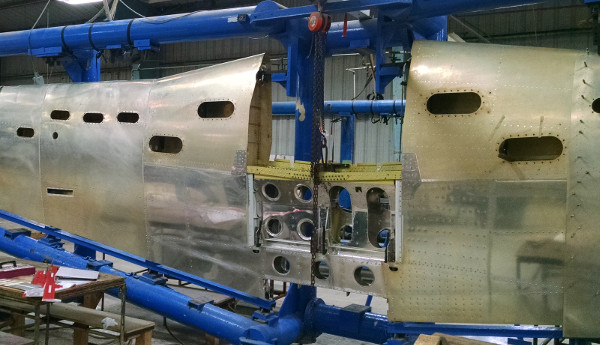

As usual, there were tours of the Mooney factory. Here's the final

assembly area:

And the wing assembly jigs:

The oval holes in the wings are fuel tank inspection/service hatches.

These mooneys will have fuel tanks that fill more of the wing than

mine. My tanks only have three service hatches per side.

I dropped of the rental car just as the storms hit. So I ended up

chilling in the FBO for several hours. I actually used their pilot

nap room to make up for having such a short night. I left

mid-afternoon; too late to make it halfway home but early enough to

get fuel in Meridian Mississippi again.

So I grabbed a hotel there for the night.

The saga of leaving Meridian the next morning will be the next post.

Ok, so we're up to May 2015. After the long annual, I had another trip scheduled. This one was a weird double-trip that happened because a work event ended up being the the week that I had a (previously scheduled) Mooney event in Texas the following weekend. So what I ended up doing was combining the travel for the trips. I few myself to Austin, Texas in my plane, then the next morning, grabbed a United flight to Oregon via LAX. I did the work event in Oregon, then flew back to Austin. The Mooney event was in Kerrville, which is near San Antonio. My plan had been to fly my plane from Austin to Kerrville, but when I got to Austin from Oregon, the weather was crappy enough that I just rented a car instead. I drove the car to Kerrville, went to part of the event, and then drove back to Austin early early the next (Sunday) morning. The trip back is another story.

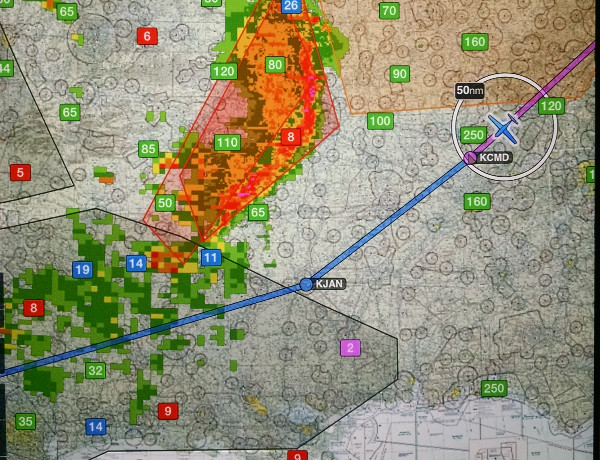

The trip down was exciting. The whole lower midwest, including a lot

of Texas, was being hit by thunderstorms that day. Here's the view on

my iPad dodging the storms on the way down.

I stopped for fuel in Meridian, Mississippi. It's an army pilot

training base, so my Mooney was parked among a bunch of army training

airplanes.

I staying in Meridian for a while, waiting for the storms to pass. I

left there with enough time to get to Austin just before dark.

The next morning, flying out of Austin, United had a fantastic system

for getting boarding groups lined up. This is so much better than

most other airlines where people sort of hover around the boarding

gate until their group is called. It was noticably faster.

Leaving Austin in someone else's plane.

Coming into LAX, we could see the big canals that are used in lots of

movies.

And lots of big interchages.

At work in Oregon, this is the villiage just down the street from the

resort where our meetings were. Here's my "Prisoner" throwback

selfie.

The weather for most of the trip was pretty temperate (if stormy), but

one morning during the trip we got snow. This is the view out of my

room in the evening.

All for now. The next entry will continue with being back in Austin.

The holidays were great. They were relatively short, but that worked out well for us. No snow this year at the mother-in-law's. The kid had his first Christmas, and got pretty spoiled, which worked out pretty well.

And then we all got sick after we got back, so January was really busy once we were recovered from everything. The kid has a passport, so the long slog of adoption paperwork that started February of 2015 is basically done. His paperwork for applying for stuff will always be slightly more complicated than for other people, but he now has ID that shows he's a US citizen and he can fly on planes with official ID and stuff.

I've been trying like heck to get ahead of things just a little bit; only slightly successful. I've been going through some tubs of "need to go through this" stuff that I filled when I moved offices about 2 1/2 years ago. Once through those, then I'll hopefully get back to working on unsorted boxes from the basement.

And I'll be trying a little bit to be a producer not a consumer. Youtube has been really bad for that. It figures out what I want, and it can always show me something that I'm interested in. It knows I like space stuff, and computer stuff, and some narrow slices of car stuff (and it's good at guessing what).

Thus trying to get back on the blogging bandwagon. Internet pal Wil Wheaton (at wilwheaton.net) had until yesterday an unbroken blog-entry-per-day streak from December 1. He and his wife Anne were in the Womens' March in LA yesterday and there's no entry from them, so they may have gotten home late and he didn't write. So I'm trying to hold up the tradition in a weird way.

More on politics in another entry. This one is just to prime the pump. Talk to you later.

A few photos taken in and around the time of the long annual. The

cats looking resplendant.

And again.

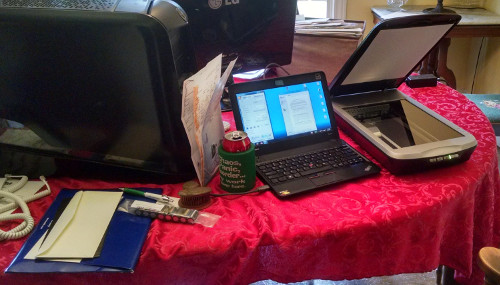

Also during this time, we were gearing up for a big project that went

over the summer through the fall. We'd been thinking about adopting a

child internationally, and this spring we got serious about it. It

involves a LOT of paperwork and scanning and stuff, so here I'm doing

that.

Among the various paperwork required are statements about your

household and asseets, so I took an artsy photo of the house,

and had to go to the local police station to get fingerprinted

(slightly odd).

One other thing:

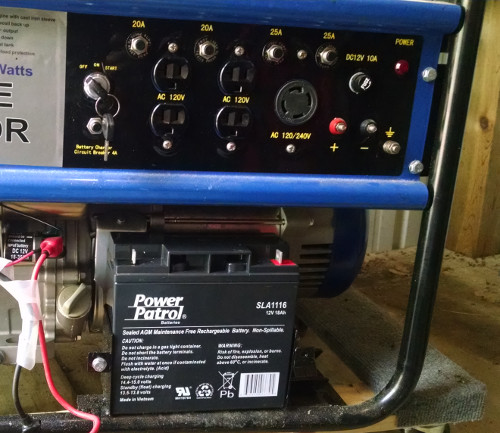

While I was at the parent-in-law's that spring, I went to the regional

battery store and got a proper battery for their generator. It's

shown here, installed.

This brings the chronology up to May 10, 2015.

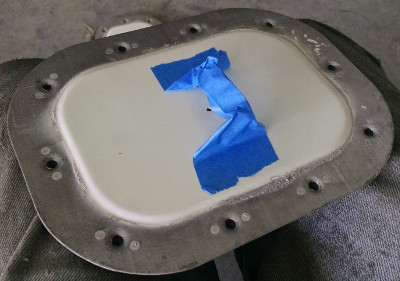

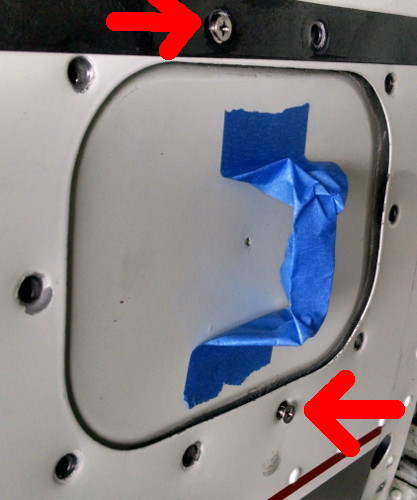

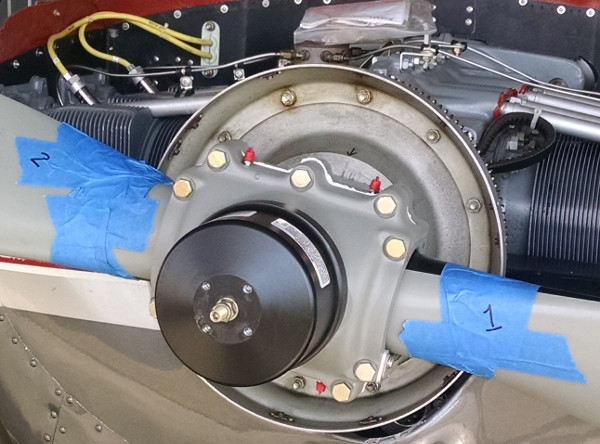

Spinner bulkhead re-attached with new hardare.

Getting inspection panels re-installed without dropping them inside

the plane is sometimes tricky, especially

when they're on vertical walls. Here's the trick my mechanic taught

me about that. Form a handle with tape:

which allows you to hold it in place until you get the first couple of

screws attached:

All buttoned up, ready to fly.

Getting ready to fly the plane home after the annual; charging all the

things.

Heading home, loading the plane.

April/May 2015 was the first annual for my airplane since the propellor was replace and engine overhauled in 2013-14. This was the first semi-normal annual. Still plenty of work done, but not major systems were replaced.

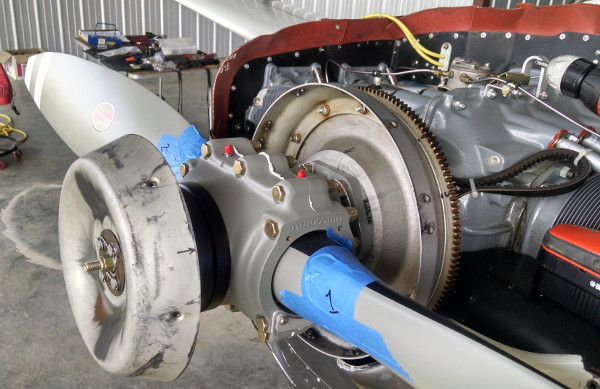

Taking apart the spinner to annual the propeller.

The pressure plate was a bit rusty and wasn't holding pressure on the

front spinner bulkhead.

We painted the pressure plate so it at least wasn't corroding.

Prop dome with the spinner bulkhead removed.

Electric fuel pump, fuel selector and fuel system sump at the bottom

of the photo.

While parts came in and we worked on stuff for the annual, I was

driving my father-in-law's truck around.

When we had a break, I took a couple of days and drove to HQ and spend

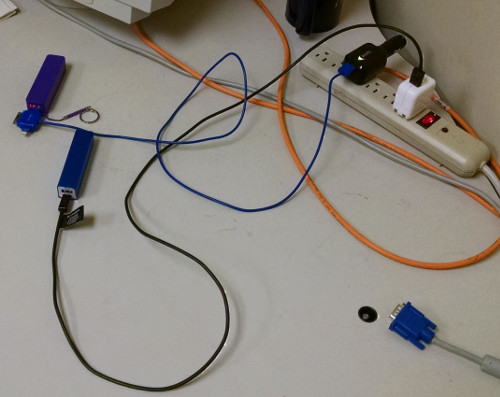

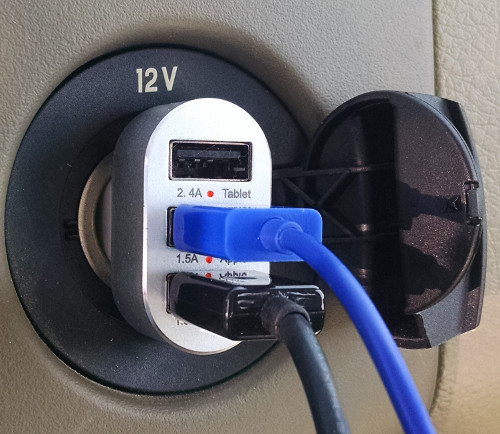

a couple of days in the office. Here's the office recharging setup.

I spent a good bit of time during this trip testing chargers in the

truck for use

in the airplane.

Back to the annual, all the belly panels off.

It was my first time taking the panels off. Over a couple hundred

screws; I stripped three and had to extract them by cutting a slot

with a dremel tool.

We did some work on the landing gear. Here's the plane on jacks, gear

retracted, looking vaguely Airwolf-like.

It's been a long fall. And November was very rocky, for various reasons. Oy. Mostly the election. Double-oy. I frankly still have an emotional hangover from that, five weeks later. But trying to put the pieces back together, I guess I'm also trying to resume normal life.

So last time I was blogging about the past, I was back up through April 4, 2015, roughly. We continue the narrative from there. I bought a new phone then, so photos since are from my current phone, the Droid Maxx, which I got because it has MUCH better battery life than the LGE.

Here's Pangur reviewing the Verizon bag my phone came home in:

and the other cats editorializing what they think of all of this:

I was still working on commissioning the front stoop/porch. The gate

didn't close well with two hinges, so I added a third spring hinge in

the middle.

And finally, my mother's mother, who had been in declining health for years, died in such a way that we had a time window to go to the funeral. My wife and I flew to Omaha and then rented a car to drive up to South Dakota for the funeral.

In all my travelling for work starting in 1994 through now, twice I've

randomly received a cheap rental car upgrade to any car on the lot.

Once in 2010 when I was in Minnesota to get my instrument rating, and

the other was trip I took in March of 2015 to California via

Minnesota. I was all prepared to get compact sedan, but she wanted to

get a fun car too, so we got a Dodge Challenger:

The drive up was along Interstate I-29 along with Missouri river

valley, which has an 80 mph speed limit. We spent the time driving 85:

What was amazing was we got almost 30 mpg. The engine was only

turning 1800 rpm:

It had Sirius Satellite Radio. Of course, this was on:

Not much of an entry, but I wanted to get back into it. That takes us through April 12, 2015.

Now that the summer is winding down, but full fall semester hadn't

settleed in (that happens today) I had a bit of a chance to get ahead

on some house projects. I have to say I'm still loving the

solid-surface countertops we put in in 2007. Here is the sink,

freshly cleaned for the first time in a while:

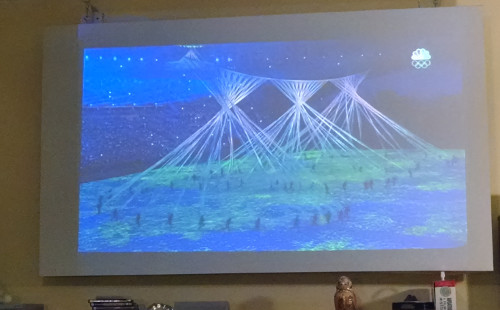

The 2016 Summer Olympics started just before the fall semester, and

since we have another person in the house, we wanted to be slightly

better set up for watching sports and eating in the TV room. We

re-arrange the TV room so that most people had a place in front of

them to eat, so that we don't have to have massive amounts of TV

trays. Here are two seats along the right side of the room with their

own tables.

Brats and hot dogs to roll in the end of summer and the Olympics

opening ceremonies.

Opening ceremonies on th big screen.

We've been able to clean sort stuff that hasn't been really clean in a

while, including the freezer.

We watch the Olympics on the big screen, onto to which we point a

projector:

One of a our long-term problems has been the input filter on the

project. Here's the cover; it's kind of an irregular shape:

The original foam filter disintegrated when I tried to change it. I

put one in of a too-heavy cloth, and it's overheated several times in

the last year. Before the Olympics started, I replaced that with a

couple of layers of cheese cloth cut to fit, and that seems to have

fixed it. It's now run for a couple of all-day stints without a

problem.

A random picture of the cats.

Thrice is under the table, chilling. Pangur is on top, looking

intently at the hummingbirds that are at the feeder we put out on the deck.

On our other big sight-seeing day in Houston, we went downtown and the USS Texas memorial ship, and the memorial to the Battle of San Jacinto.

Battleship selfie. You know, like you do.

My wife, on one of the anti-aircraft turrets, taking aim at plagerism

and comma-splices.

A lot of the gear on the battleship still kind of works, which is

cool. This turret doesn't shoot, obviously, but the articulation

works.

Bridge, which we couldn't go into but could photograph.

The engine spaces were amazing, but it was difficult to get photos,

because everything's massive but you can't tell because there's

nothing for scale. I did snag one photo of the engineering main

instrument panel:

The battle site is an interesting walk-around, but not a lot to

photograph, other than plaques and a lot of grass. The memorial

itself is amazing and huge. Here it is looking like one of the final stars in

Super Mario 64:

Everything really is bigger in Texas. Driving back to the house, we

have to wait for a crossing oil tanker.

(I think we were actually waiting for the ferry, but I liked the photo.)

Flying back home, gratuitus instrument panel photos:

One nice thing about this trip was that it was the major long-distance

trip that my wife and I have attempted to take in our airplane where

everything went flawlessly. Two legs out, two legs back, the airplane

was completely consistent and dependable.

Continuing a series of posts that I last worked on, in....er.... February, one of the places we visited in Houson (visiting my brother and sister in law) was the NASA Center in Houston. As a space nut, this was a pretty awesome trip.

The guest rooms we stayed in were very well-equipped:

While we were out on the town for a day, I charged all my stuff.

A few highway photos while we were driving into town.

Houston is VERY big on flyover-overpass exchanges. Here's a good example.

A bit of skyline.

Another overpass set; at least three layers!

A lot of the stuff on display at NASA in Houston is so big that it doesn't particularly lend itself to photography without serious wide-angle gear, and I just had my phone. I attempted to take a few shots to commemorate the occasion.

Here's one of the shuttle carrier 747's with an engineering mock-up

shuttle on top of it, parked outside the museum:

Another highlight of Houston NASA is that they have a complete

Saturn-5 laid out in a horizontal display building. This is looking

down the first stage from the second stage. The first stage is

sitting on its ground carrier vehicle; look at the enormous tires!

An (I'm guessing) engineering test Command Module (the brown bit) with

its escape tower on the right.

As of this trip, I have now seen all of the Saturn-5 rockets on public

display in the US. There's one at Saturn Apollo Center at Kennedy

Space Center in Florida, there's this one at NASA in Houston, and

there are two at Huntsville, Alabama, one inside like the other two

are, and one stacked vertically outside (which is REALLY impressive to

see). I've read there's one more Saturn 5 first stage outside

somewhere in Louisiana; maybe I'll go fly over it someday.

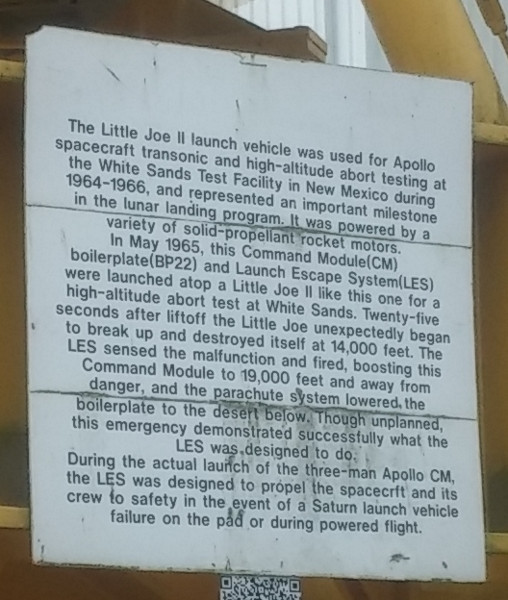

Outside the Saturn 5 display building, they have some rocket engines,

and this. It's a "Little Joe" test vehicle that NASA used to test the

escape system for the Apollo Command Module. You can see it here,

sitting with a command module mounted on top of it.

Another flyover interchange.

Oh, right. The *other* thing that's been going on in our lives is that we've adopted a kid. We started the process of international adoption from China last February (2015), aiming to travel to China in May of 2016, right after the end of the spring semester. We managed to hit that perfectly; we travelled in May the week that my wife finished finals.

The paperwork process is long and annoying. I may post about it sometime. It involved background checks and lots of getting verification of the previous layer.

Early in the process last year, the adoption agency we were working with started a program bringing kids from China who were in danger of aging out of the adoption system and bringing them to the US for three weeks. We were part of the way through our initial paperwork, so when the social worker was at our house, we talked about that program. They had a couple of kids still without host homes, so at that point we decided to sign up. It was a way to try out parenting and help the program, without the commitment to keep the kid.

Not surprisingly, one of the things that can happen (and they hope happens) in the hosting program is that the hosting parents fall in love with *that* kid, and decide to adopt them. We definitely did that. We wanted to answer three questions with the hosting. 1) Are we capable of being parents? 2) Do we want to be? 3) Do we want to be parents to *that* kid? By the end of the three weeks, we knew the answers to all three questions was YES. So once the kid had headed back to China, we formally requested to be able to adopt him specifically, then continued the rest of the paperwork.

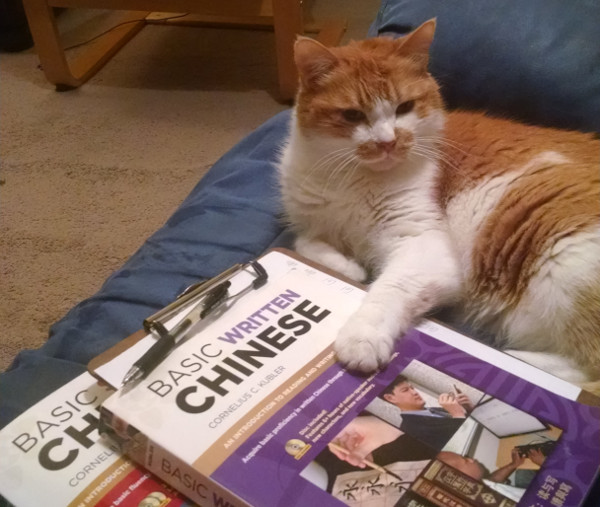

One of the things my wife and I did as preparation for the trip and

for adopting a Chinese child who didn't speak english was to take a

year of beginning Mandarin. Here I'm taking one of our exams in the

second semester. One of the dialogs was all about location words. So

the dialog is about the computer that is ON the desk, and the dog that

is UNDER the desk. The teacher had props for the dialog, which I

thought was hilarious.

We flew out of Lexington to head to China for the adoption. Our

flight was early enough in the morning that we got a hotel room with

shuttle service to the airport. Here are our suitcases, ready to go

to the airport for the big trip.

A nice, auspicious sunrise on our initial climbout.

The adoption took place in the province of Jinan, China. My wife,

kid, and me at the big central park in Jinan City. The sculpture in

the background is reminiscent of the Mandarin character for the name

of the city.

There will be more posts about our trip and about raising a kid, but I wanted to get the topic out there.

While I'm catching up on the status of things....

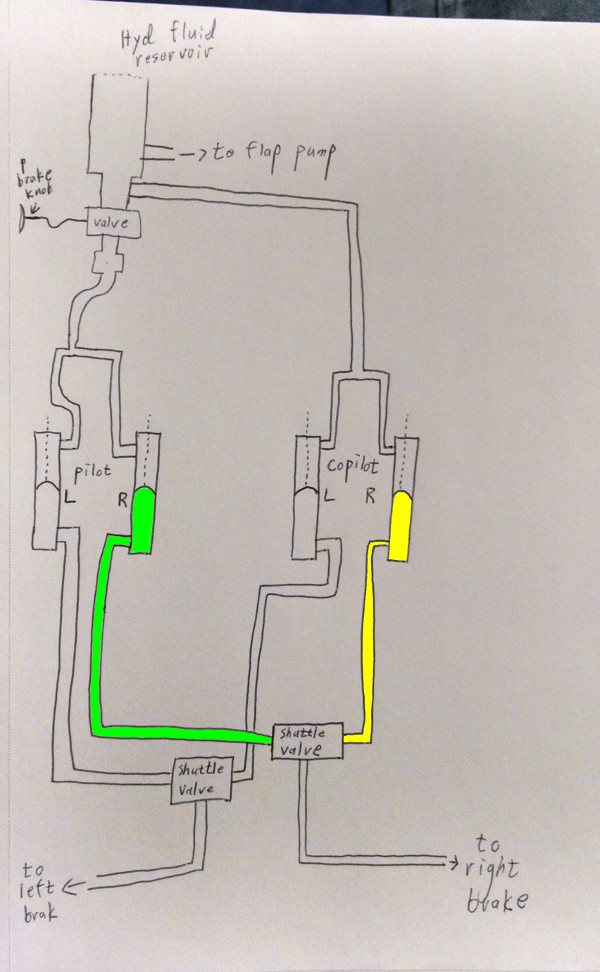

The plane is fine. In the annual this spring, we dug into the hydraulic system. The hoses were original, and pretty stiff. The flap up/down control was super-stuff. It turns out I was wrong about the diagnosis of that; it was the cable, not the pump. That's fixed. The retraction speed is fixed. We don't really know what the problem is with the pump that had been in there, but I bought another one and that one worked fine. I still have the bad pump to try to figure out what was up.

The brakes still act slightly funny; it will be interesting to find out if it's better or worse when it's cold. We'd decided that the old problem with the mag checks might have been a weak plug, so we put a massive back in the bottom of #2. However, a couple of flights later, I had another bad mag check, so bought and installed a brand new fine-wire plug there, and it's been fine ever since.

I need to take it down to Knoxville tomorrow to get its IFR sign-off. After that, I can start flying it more, potentially.

My blog server had pretty severe bit rot. I hadn't kept up with the site maintenance, I'm afraid. I don't know exactly what the problem is, but for at least this calendar year, I coudln't reboot the server without serious work to get it back running again. I think what probably happened is that something in the emulation layer got out of synch with something in the packaging, and so it just woudln't boot correctly. I got the great folks at my hosting site, vps.net to get the server running again a couple of weeks ago, and so I managed to pull a full backup, but then within the last week it died again.

Ove the past couple of days I backed up the backup, so I have everything from the old server image in multiple places. Last night and this morning, I bit the bullet and had the server completely re-installed. Now I've re-installed everything from the blog. If this entry shows up (It will be the first August 1, 2016 entry) then we know it worked.

When doing stuff like that, you discover all your sins in the installation. Like the fact that the blog is all packed into /var/www like it should be, but some of the support script are in a directory in my home directory. Ooops. And the includes are scattered around in wierd places.

More on that in a while. The house is fine, the cats are fine, the plane is fine. The family is fine, and has had another (human) member added to it, which is very exciting.

All for now. This has been a systems test; please ignore. If this were an actual blog post, I'd have a picture of an airplane instrument panel or some electronics or some such.

A schematic map of the brake system in my airplane. Figured out from looking at the hydraulic lines in the airplane.

Then at the end of March 2015, I flew my wife and I to Texas in our plane. It was pretty awesome. First we had some prep. As part of that, I made a tool to try to not make too much of a mess of the plane when removing the oil filter, which I needed to do to change the oil. (I *really* wanted to have summer oil in the plane before flying it to Texas in April.)

Bandsaw out.

Saw some 4-inch PVC pieces to shape.

Primed, painted, and ready to glue together.

Here's the finished piece, sitting below the oil filter. This is a

catch pan to sit under the filter as you unscrew it from the back of

the engine that catches most of the oil that drains out of the filter

itself as you disconnect it. That keeps that oil from running down

the front of the firewall and out on the nose landing gear tire and

making a mess. (In the later oil change, I discovered that leaving it

to drain for a couple of hours to let the filter mostly drain also

helps a lot.)

It was supposed to be chilly the morning that we left, so I took

advantage of the engine heater we'd recently installed. Here I've

plugged the source end of the extension cord into a light timer.

The other end plugs into the heater plug inside the cowl; here you see

the end of the extension cord going into the oil door.

I got the Stratus mounted and power cables run to it, so that I could

use it all the way down and back. A nice addition for long-distance

flights.

Flying down, I took the Stratus out of its mount on the windshield

because it seemed to be overheating. I was very amused to see that it

still picked up ADS-B ground stations and GPS signals just fine,

sitting here on the throttle and having no view of the ground and

almost none of the sky.

We flew the whole flight down IFR. We took two legs to fly it. Flying into KIAH at the end of this flight was my first time flying into a class B. It was fun and interesting. The controllers were very nice to me. Taxiing was fine, except for my blowing my taxi instructions slightly and getting yelled at by the ground controller.

The FBO was clearly used to bigger planes, but they were very nice and

accomodating. They parked our plane along their flight line, with

cones to make it more visible.

There's a plane taking off (indicated by the arrow) on the runway

right behind our plane. Neat!

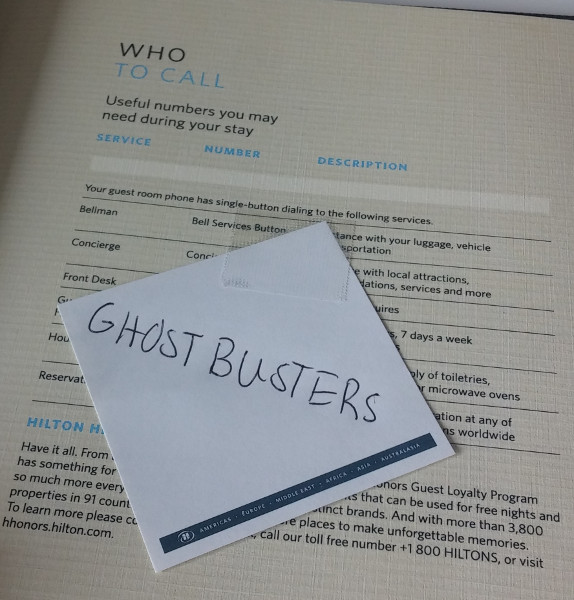

After I went to Minneosota, I went on for the real purpose of the

trip, to California to the GPU Technology Conference. When I got to

my hotel, I opened the hotel directory to look something up, and I

swear this was on the page as I opened it:

One interesting thing about this (clearly well-funded) conference is

there were several neat cars in the conference center hotel:

I think that these were there to advertise some outing that the

conference was advertising. I looked into it; it took more than half

a day, so I decided not to do that.

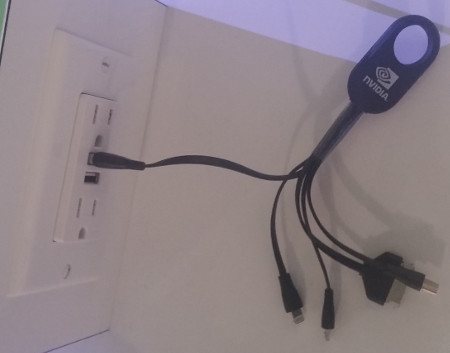

Interestingly there were a bunch of power pods around the conference,

with power cords set up for charging. (NVIDIA was the major sponsor of

the conference.)

Given all of the security problems with plugging a USB device into an

unknown device, I'm slightly surprised that they did this. But people

definitely used them. It's definitely not the sort of thing you'd

want to do at DEFCON, but that's another story.

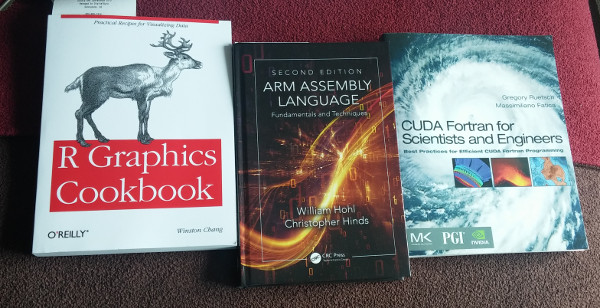

I picked up three books at the book store:

The hotel was really close to the San Jose airport. Most people

probably woudln't/don't think that's an asset. But it was great

watching airplanes flying over low.

The view out my hotel window. The view did not suck. I grew up and

mostly have lived in the midwest, so having palm trees immediately

outside of my hotel is terribly amusing to me.

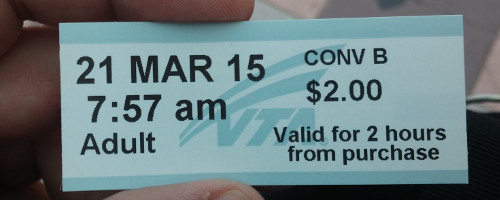

I rode public transit around the bay area while I was there. Not

something I do strange cities very often, but I'm really pleased how

well I did. I took the train up to Mount View to have lunch with a

friend, and came back one evening.

Out waiting for the train, saw another plane flying over.

I realize that Buffy the Vampire Slayer was in SunnyDALE California,

rather than Sunnyvale, but this station amused me nonetheless.

I stayed in California one extra day at the end, so I went to the

Computer History Museum in Moutain view. It's AMAZING. They have

tons of fantastic artifacts.

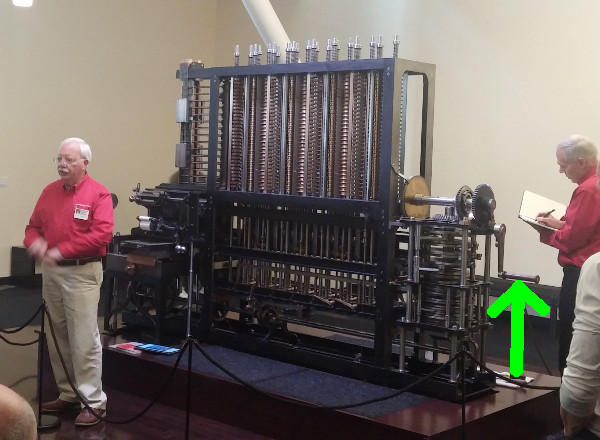

Here is a Babbage Difference Engine that someone built. It's a

mechanical that was envisioned (but never actually built) by Charles

Babbage. When people talk about "turning the crank" in a calculation,

the crank is indicated the green arrow. Apparently turning the crank

is an important very skilled job.

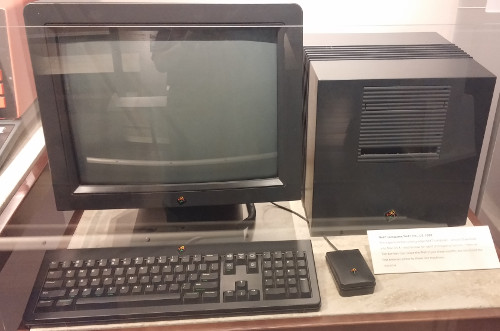

A NeXT Cube. With the original WORM drive, even. I don't know that

this is the machine that the World Wide Web was created on, but it was

on a machine basically identical to this.

The museum has a PDP-1 computer from DEC. Here's the front, with

racks of paper tape for the loader and the paper tape reader. It was

pretty cool to see it play Space War.

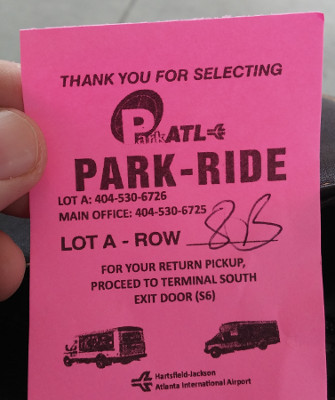

And then I flew home to Atlanta. This was directly above the parking

lot where my car was. I would have loved to stay and watch airplanes

for an hour, but since I started on the west coast, I lost three

hours, so I needed to head out so that I wasn't getting back *too*

late.

One of the things that frequently bogs me down in blog posting is when I have a post to make that has a ton of photos, I end up not doing the post for weeks because I don't have the time to put together to edit, crop, and prep them. So the really good, dense posts end up being the ones that slow things down. So for this post, I'm just going to split up the posts, and do the image editing and writing when I have time to do them separately. So this is part 1 of something, maybe 3 for the whole trip.

In March of 2015, I took a trip to a conference in San Jose, California for work. The conference went the entire week, starting on Monday evening and going through Friday. The airline flights lined up in a wierd way; there basically wasn't any way to construct the trip to fly out of my normal airport (Knoxville, TN)(TYS) without adding several hundred dollars, so the base price ticket would have been flying out of Louisville, which more than I want to normally drive.

So I set the cost of the base ticket by the Lousiville flights. But if I'm driving out of Lousiville, I might as well drive slightly farther and fly out of Atlanta. That gives me MUCH more flexiblity in picking flights. In fact, it gave me enough flexibility to actually add a whole leg to the trip by only kicking in a bit more on the tickets myself. So instead of flying directly to California, I flew out of Atlanta to Minnesota first thing on Saturday, spent the weekend visiting family and friends, and then flew from Minnesota to San Jose on Monday.

Just about to leave the house at 04:20 in the morning. It amuses me

that the clock with four hands (the long red one is the 24-hour hand;

it's just after 08:20 GMT) are all pointing in basically the same

direction.

It was first thing on Saturday morning, and it was a relatively warm

spring-like day. There were a ton of people out at that time of the

morning towing boats; I presume for the first outing of the spring.

By the time I got to the I-75/I-40 split on the west side of

Knoxville, the sun was a bit up.

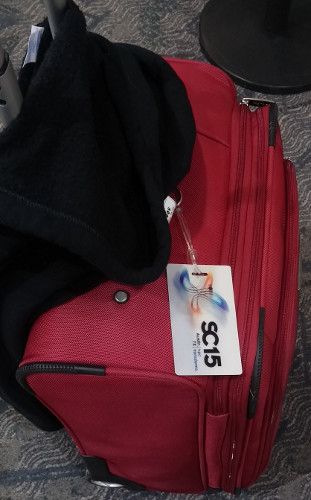

My suitcase, notable because it's bright red (easy to spot if they

tell you the wrong carousel by one) and for having a tag for a

conference that hadn't happened yet.

And it got interesting when we got to the airport. Enterprise rental

at MSP apparently had a surplus of cars, so they were offering to

upgrade to anything on the lot for a very small sum. They had an

electric blue almost-new Ford Mustang on the lot, so I took it.

The dash on the Mustang was interesting. The center box can be

configured for a number of different things. It can display text

gauges:

or quasi-analog gauges:

The "vacuum/boost" gauge is amusing. One, because I'm pretty sure

that car wasn't turbocharged. Also, I paid attention to that gauge

while driving. It probably was connected to some sort of manifold

pressure sensor, but it definitely wasn't reading true, or else the

zero was (possibly deliberately) way off. To get the gauge to come

anywhere close to 0 vacuum, you should have to bury the accelerator,

and I could get it to hit "zero" with only moderate acceleration. Ah

well, probably for the best.

So I visited family on Saturday. But I decided that with a magnificent car like that, it was a moral imperative to a least do a little road driving with it. It would be a shame to have something like that and just stay around the Twin Cities. So I pinged a college friend, who also lives in the Cites, and proposed that we take a Sunday morning road trip down to our alma mater. She was game, so I headed up to her house first thing Sunday and we did some driving across the state. The photos from the trip itself will be from the next post.

The Minneapolis skyline over the hood of the Mustang.

Me, ready to road trip. I kept me in this photo mostly because it

amuses my wife.

This trip continued in a future post.

Photos that amuse me. I was driving somewhere and messing with the

Stratus with ForeFlight.

The rest of the stuff from early 2015.

The three cats enjoying the snowy view. It was really really cold in February:

February was the first big round of adoption paperwork. I sent the

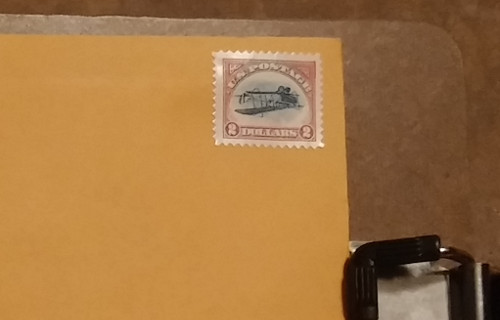

first application packet with a commemorative inverted-Jenny stamp. I

figured we could use all the luck we could get (so far it's paid off;

things are going well).

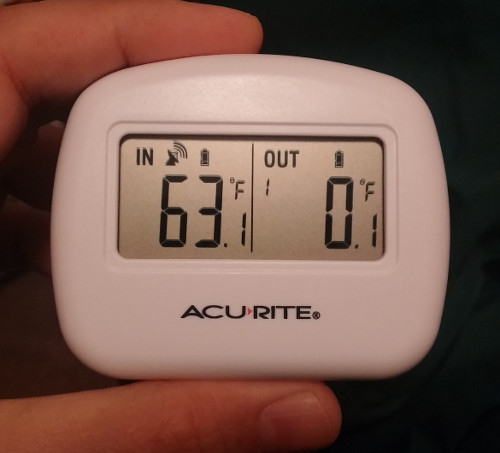

Again, cold while driving.

And snow coming down. I highlighted a couple of big flake clusters

with arrows.

One step back. We managed to leave a hose on the front spigot, and

the cold weather froze the tap, and the valve had a crack in it when

it was open. Here's before:

And after:

(As of this writing, December 27, the outside tape is still broken.

Argh.)

Oooh--another technical success. And this one I did once and is

finished! I replaced the plug on the vacuum cleaner:

And one final photo of Pangur and Thrice watching the snow.

Before everything got crazy in March, here are some overall posts that kind of cover January and February. In two separate posts to avoid photo overload.

I am ever-so-slowly collecting parts and tools to put my 1972 VW

engine back together. I'm going to tap the case to plumb in an oil

filter. To do this, I got the proper drill bit, tapered ream, and 3/8

NPT tap:

And, in a fit of organization, I put them in a box and labelled them!

Amazing!

Rare picture of all three cats:

A minor home improvement. This is in the "library" on our ground

floor. I put a rack for coats on the left wall here, so that when we

have coats to hang up, we can do it somewhere other than the official

coat closet in the center of the house which is far away from the

doors and also where the cat food lives.

Pangur disapproving of whatever I'm saying on the phone.

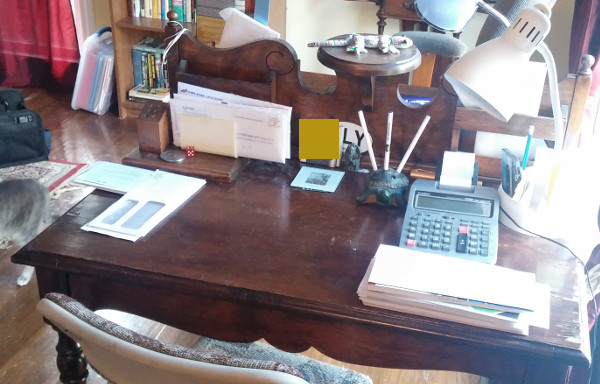

I made some moderate effort earlier in the year to organize my stuff

on the main floor (culminating in the drawer that serves as a desk

from the last post). Here's my half of the library table desk

organized (which I'm sure was short-lived, but an important step nonetheless).

Also in the organizational front, I got some nice storage trays from

Harbor Freight and made organization out of the chaos of the socket trays in the

tool box.

And finally Thrice doing her Meerkat impression.

At the Cabin over Christmas. Burning paper trash here. I just liked

the shot of the burn barrel and the creek.

It's been a hell of a year. As of October, all of the settings of the Back to the Future movies are now in the past. Our "Log In Date" for our adoption portfolio was mid-November, so that's exciting. We're taking Mandarin Chineese (mostly spoken, some written).

Aaaaaaand my father-in-law died a couple of weeks ago. :-( Thus we ended up here longer than expected, and we had (and still have) lots to do. Oy. An ugly transition. Very sad. We're still getting used to it.

So I'm going to try to get posts up that summarize the interesting bits of the year. Here's the one for this trip.

One interesting thing: my wife and I gave this record/CD/tape

player/radio to my father-in-law in...it must have been 2002. I tried

to play a CD in it, and the drive is jammed. Apparently he used it so

much that he wore out the drive mechanism. I'm incredibly gratified.

This is the back of the Explorer about to head back from the memorial

service. The cylinder on the right is a 1/6th keg of beer, so that we

wouldn't run out when all the people came back to the house. We

swapped it in before the night was over. People got a kick out of my

walking across the road to the liquor store and bringing the keg back

with my funeral clothes on.

And I got some Taurus driving in while running errands; some day driving

and some night driving:

And I got to drive the Explorer a bit. It's fairly new one, so it has

the fancy digital dash.

And the climate controls are complicated enough to launch a space ship.

Charging back-up cell phone batteries. The cable is obviously better

because it has glowy lights in it. :-D The charger is one of the a

great set of Sprint chargers that are both car chargers and wall

chargers, and they have lights on them.

My Christmas present to my self is this comically large tap handle. I

got this because I'm going to tap the engine block of my VW for an oil

filter, and the tap is large enough that it doesn't fit in a normal

tap handle. The beer can is for scale.

I was sitting on the couch studying for my Chinese language final.

This photo is absolutely not posed; Jasper came, sat down with me, and

put the royal paw on my books. I think it's a hilarious pose; it's

great that he looks so stern.

I've had a long-term project around the main floor of the house to

kind of get my stuff organized in a longer-term way. I like having a

working desk that I pile stuff on to work on or sort, but of course

that gets piled up. So I cleared out this drawer, so it can be the

"to be sorted" or "to be gone through" piles, so it's out of the way.

Of course, as is no surprise, Pangur is helping.

All for now. More entries on the year as I get photos edited.

Wow. What a year I've had since February. February was vey snowy, and March wasn't any different. (All the things I mention in passing here I will hopefully write a whole blog post about with photos. I just want to get the sequence down here while I'm thinking about it.)

At the beginning of March, I worked with my wife on her professional organization's conference, which almost got snowed out. So the planning and the aftermath of that took more time an concentration than we expected (we drove there and back; much snow). In the middle of March I took a conference trip to San Jose California (flew commercial). On the way, due to airline weirdness, I spent a couple of days driving around Minnesota. Then the conference in California, and then I spent a day at the Computer History Museum in Montain View, and then flew back home. Then, with less than a week at home, I flew wife and I to Houston to visit her brother there. Much touristing was done, then we flew home.

April: Got a front mini-porch put on the house. Got a new phone. April 6, my maternal Grandmother died, so my wife and I made plans to fly up to be at the funeral. We flew up on April 10 and back on April 12. Then the rest of the month was getting my airplane annualed. This was the most normal annual I've had, but still, it ended up being extended for a week because we had to get a part of adjust the front landing gear.

Plane annualed and flown home at the beginning of May. Mid-May, flew my plane to Texas (dodging storms), then flew commercial to Oregon for a several day work thing, then commercial back to Texas. Then a Mooney event in Texas, and then attempted to fly home. Got to Mississippi; the electric pump on the plane failed when I went to fly home. So that was a week and change of wrangling to get that back.

Sometime early in the spring, we decided that we were going to start actively pursuing an international adoption from China. We decided to target bringing the kid home in summer of 2016. We spent a lot of time in May, for instance, sending out from background checks from all the states we've each lived in since turning 18 (turns out I've lived in several.).

The first big component of the paperwork was the home study. This included three visits with a social worker. The first two were in May, the last one was June 10. During that visit, the social worker talked about their upcoming hosting program. We told her that we hadn't been interested, but it turns out, they'd lowered the fees. So we decided to sign on.

So as of June 10, suddenly we were preparing for having a kid in the house. So things suddenly got super-busy. June wasn't bad; I didn't have a lot of trips, but lots of paperwork and working in the room that our guest would be staying in.

At the beginning of July, we went (flew commercial) to Minnesota to Convergence. Then we came back and spent time finishing prep for the kid. He arrived on July 16th, and flew back to China on August 9th. That's a whole story for another time. The conclusion is that we can be parents, we want to be parents, and in face we're going to pursue being parents to that child (which you can do if you're the host family).

So now starting 3rd week of August, my wife and I are both taking spoken Chinese. The 2nd weekend of September, we went to the planning meeting of the conference that organization will be throwing in March. The next weekend we hosted a Chinese Med School instructor (I took him flying). This weekend my wife is at a conference; but I'm writing this blog post because this is the first real chance I've had to catch up in forever.

Yesterday and today I ordered a bunch of parts for my vintage VW. I hope to put it back together in a few weeks.

Phew. Just typing that made me tired.

Final answer: busy summer, and we're super-excited that we'll be adopting a really great and sweet kid this coming year. Not a ton of flying, but some good stuff in March and in May.

Details on a lot of this stuff in the (hopefully near) future. This was just the overview. Photos too.