A vintage car is never done. I'm doing the brake and wheel bearing on my beetle project because I want that to be a "done" item for the next 30,000 miles that I drive the car, but even doing a job like that, you find out other things that need to be worked on.

One of the things that are often done is to have the brake drums "turned", or resurfaced to provide better braking friction. The important surface of the brake drum

is the inside surface where the brake shoes rub. Because resurfacing the drum is removing material from the inside diameter, there is a maximum diameter that is allowed before the drum should be replaced:

So the interior diameter of the drum should be 9.822 inches or less.

Up until today I didn't have any measuring instrument that could measure a diameter that large accurately enough. I went to Sears and bought a combination square with a stainless steel ruler marked in 32nds of an inch, long enough to measure the brake drums.

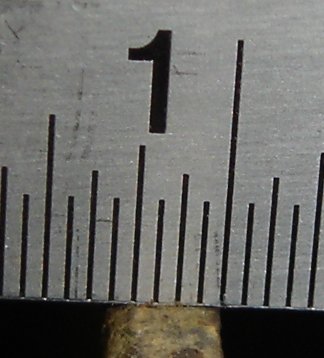

Here's the ruler set up to measure the drums:

9.822 inches translates to (in very non-standard notation) 9 and 26.3/32 inches.

To maximize accuracy and eliminate the quality of the machine work on the end of the ruler, I placed one side of the drum exactly on the 1 inch line (which means that you have to subtract one inch from the measurement you find on the other end):

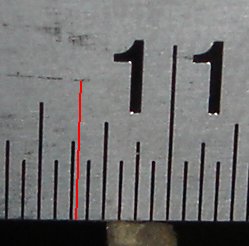

Below I've marked a red line at 10 26.3/32. This is the measurement of the right front drum. It's at least 1/32 of a inch too big already, without any resurfacing (that's 30 thousanths past tolerance for you machinists).

The left front drum is even worse:

So the front drums are both out of wear tolerances, which means I ought to get new ones. I already got one for the right rear because the inner surface of the drum was badly gouged, so I might as well get new all around.