In September, I wrote a very long text-heavy post about the process of internal combustion engines and what things can be adjusted.

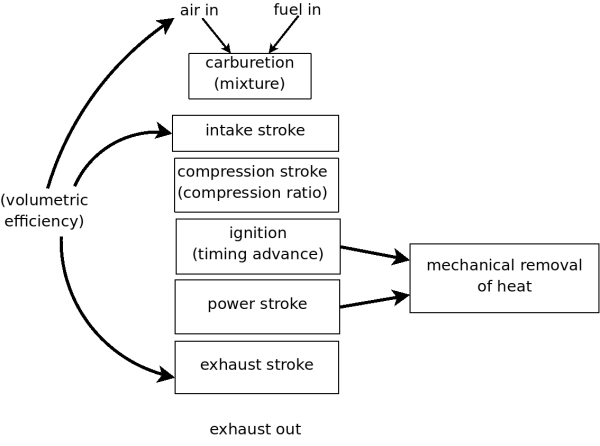

I'm getting back to that, so I've attempted to produce a diagram that partially illustrates the process here:

Each thing in parentheses can be adjusted; some things only as part of the design of the engine, others are adjusted when the engine is running. If any of the items fails to work, the engine will not run.

Adjusting the performance of an engine (of given displacement) involves changing one or more of the items in the diagram. The engineering challenge is that such a change also requires you to change other aspects of the engine to compensate.

For instance, the ignition timing and mixture are intimately involved with each other; they need to change in relation to each other for the engine to keep running. If you stomp on the gas and the engine hesitates, it means that when the throttle opens quickly (increase in the effective volumetric efficiency), the mixture and ignition timing aren't changing properly to compensate.

I put in the mechanical removal of heat because that's a critical (and limiting) parameter of the Volkswagen air-cooled engine (like in my beetle). It's essentially a function of the fin area of the cylinder heads and the airflow around the engine. There are lots of ways to increase the power being developed by a VW engine. You can, for instance, make the intake and exhaust system much less restrictive to make the engine breathe better. However, that only increases the load on the cooling system and so makes it easier to overload and overheat the engine.

My next task with my engine is to decrease the compression ratio of the cylinders down to what it should be. I think it's been increased by accident, by people adding used heads without adjusting things properly. That will decrease the burden on the engine's cooling system and allow me to adjust the ignition and carburetion systems correctly, and hopefully stop the exhaust valve from stretching.