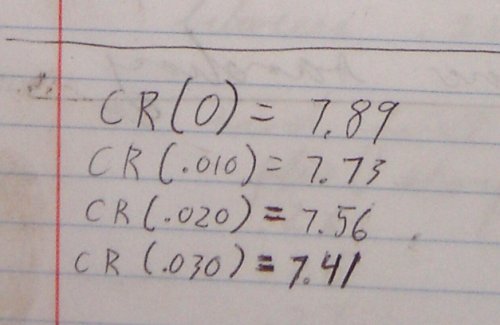

Owning a vintage car is an excersize in waiting for parts. Unless the previous owner was incredibly fastidious, you'll find as you take things apart that something was put in wrong, or had not quite the right fastener, or whatever. So my beetle is now approaching 8 months on the mend and I'm waiting for parts again. Last week I got measurements taken and I now know what compression ratio each of the shims that I have will generate.

So, I'm almost ready to put the cylinder heads on (one old, one new). In laying out the parts, I realized that the head washers were somewhat...assorted:

There's a thick washer on the right and three thin ones on the left. Of the 16 head washers, most are thin. Most of the hardware kits I've seen talk about the special "thick" washers for holding down the head. I assume that the thick ones, then, are the ones that are supposed to be in the engine. So now I have those on order.

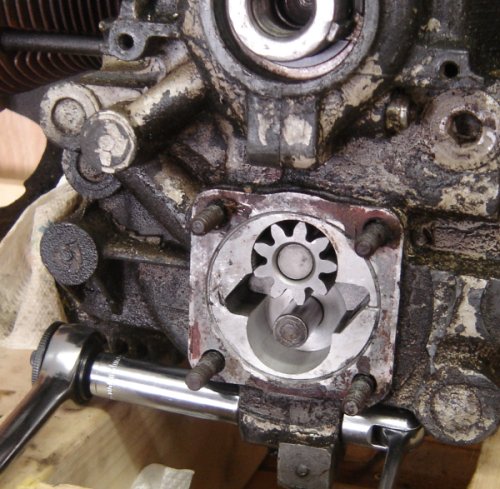

But I really wanted to get working on the engine this weekend. One thing that needed to be done is pull the old oil pump out and install the new one. First, to remove the old pump you have to loosen the case bolts around the oil pump bore so that it will slide out:

The two 13mm wrenches are on the ends of a bolt that helps hold the two case halves together.

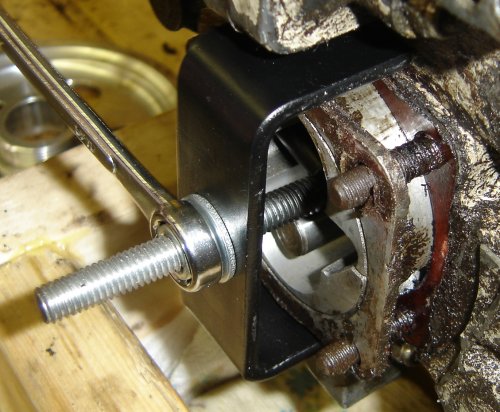

The oil pump puller doing its job:

Once I got the old pump out, I spent time following the instructions from Gene Berg that came with the oil pump about measuring the pump and the case to make sure they fit.

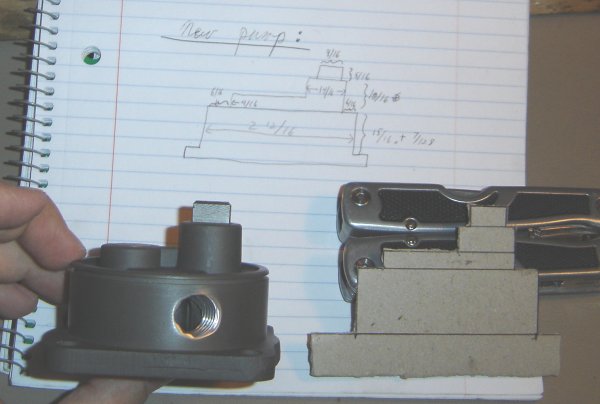

Everything matches except one. The raw measurement, according to their insructions, indicates that the oil pump sticks in too far. But the new pump is shallower than the old one. This calls for a model.

I created a 2-d cardboard template of the cross section of the oil pump where it sticks out the farthest.

then I tested that cardboard template in the actual engine

which shows that the pump comes close, but it clears.

So the pump is ready to be installed in the case

so that we can make the final measurement to make sure the driving shaft of the oil pump driven gear goes deep enough into the camshaft.

And parts are on the way. With luck, I'll have the heads on a week from now.