Ok, things moving forward on the beetle.

Air deflectors, which looked nasty

cleaned and painted with rust-eating flat black paint

Push rod tubes prepped

and painted with flat black radiator paint

Checked the chamber volume of the newer of the two new cylinder heads.

It checks out the same as the other head, so that's at least consistent.

The cylinders are cleaned, painted, oiled, and ready for installation

Oh, and I mocked up a cylinder and checked the deck height--it's the same as before, so the shims I have will be fine.

Going through the docket for today (yesterday, really), that leaves...the pushrods themselves. They're supposed to be very very straight. Using a marble tile as a reference surface, for most of the pushrods it was hard to tell that they were anything but dead straight.

Here's one that looks good

Still pretty good, although I might say that it's not quite straight

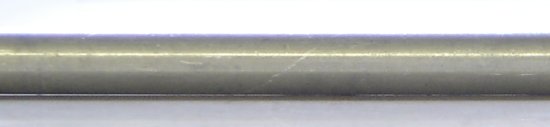

And then there was this one, definitely bent. Guess which valve this one is from?

For those of you keeping score at home, this is the right-front-most pushrod in the engine, that actuates our friend, the #1 exhaust valve that was stretching which is what started this mess in the first place. This is totally consistent from what's gone on before, I just wish I'd checked this earlier, because now I can't run the engine without a new set of pushrods.

This bent pushrod wasn't the cause of the valve problems. On its own, a bent pushrod would effectively shorten, meaning that valve clearance would get bigger, which is a normal wear pattern (the symptom was valve clearance getting smaller). However, it's perfectly consistent as a further symptom the valve clearance closing. When the valve clearance was tightened down, the camshaft was hammering on the now-constantly-too-tight valve train, and the pushrod is what gave first.

Oh, and three of the pushrods from the right side of the engine have significant scuff marks on them

which is further parallel corroboration that things were not well on the right side of the engine.

Now I need to finish cleaning the piston components, and then assemble them and stat installing stuff. Tomorrow I'd like to get the heads on and do a dry install of the valve train so I can check to make sure the geometry is right so that I can be sure to order the right length of push rod.