I've been waiting, well, since last August to make a blog post about this topic with that title.

I had a long to-do list in the garage today. Among the items I was worrying about in my Beetle's engine that I'm putting back together were the rocker assembly studs in the new cylinder heads. I think the old ones weren't sealed right, and were contributing to general oil seepage. Here's the inside of the valve gallery on one of the new heads. I've circled the stud. Keep in mind that this area has oil splashing around in it when the engine runs.

What's interesting is those heads protrude out the back of the gallery, meaning that if oil goes around the threads, it will leak out of the engine.

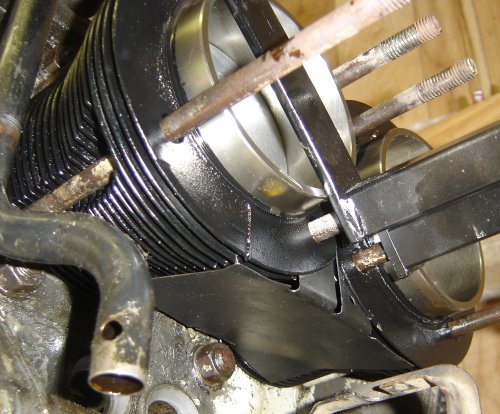

The first piston/cylinder combination ready to go on the engine, early this afternoon

And on the engine

The right side cylinders are on...but what's missing?

Ah, the all-important air deflector

Which, because I don't like how mine fit, I wired on for double-safety.

And finally, after 8 months, the engine looks like an engine again

The pistons and cylinders are in, and the heads are on and torqued. Now I need to deal with the valve train, and getting new push rods.

[The process of torquing the heads on involves going back and forth across the engine multiple times increasing torque slowly, creating a web of tension that holds the whole engine together tightly; thus "cat's cradle".]