I spent most of the weekend working on the Beetle. The only reason my wife didn't kick me out was the Olympics were on.

A brief summary follows:

I worked on cutting out gaskets old-school style (with an Xacto knife). The sockets are there to provide inner-circle templates:

When I assembled the engine, I had problems with intake manifolds fitting. Since this weekend was the first warm weather we've had in months, I collected together the manifold center sections I had and tried them all for fit.

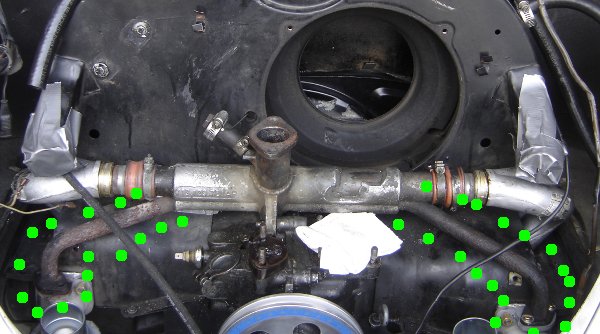

Here's the problem. The manifold bolts to the cylinder heads at the sides of the engine to deliver air/fuel charge. But there's a riser tube that takes a small amount of exhaust and heats the intake manifold to act against carburetor icinng and promotes fuel vaporization. I've highlighted the riser with green dots. The ends of heat riser bolt to the muffler, so the manifold/heads, muffler/heads, and manifold/muffler becomes a three-way all-fits-all problem.

In this example, the original intake manifold that came on the car, as installed above, the right head riser flange fits properly

but the left side does not. Here you can see that it doesn't go to the correct depth

AND the screw holes don't line up

I searched for fit problems in mufflers and intake manifolds on TheSamba, and the answer was yeah, they're like that, you just bend them into place. I found that an 18-inch pipe wrench makes a fair bending tool: