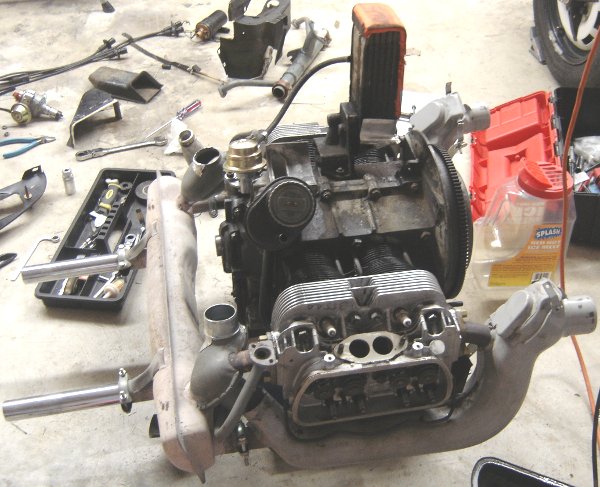

Good news on the vintage Beetle front. After pulling the engine a

couple of months ago, I've retorqued the cylinder head bolts and now

I'm putting the engine back togther for re-install. Here's the engine

as far apart as I got it. The valve covers are off and the rocker

assemblies removed, to get a all the head bolts at once.

Here's the engine a few days ago. I stopped the re-assembly

because I was a bit worried about some oil that was building up on the

front left corner of the engine, under the oil cooler. I was worried

that the oil cooler was leaking, and the time to replace it is when

the engine's out and dis-assembled anyway. However, advice I've

received is that oil coolers don't drip oil; when they have a leak

it's a hemmorage. So this last weekend I went to take off the oil

cooler to test it. The cooler is the sticky-up thing that's wrapped

with orange foam on one side. There are bolts on the bottom that I'm

going show up close in a minute.

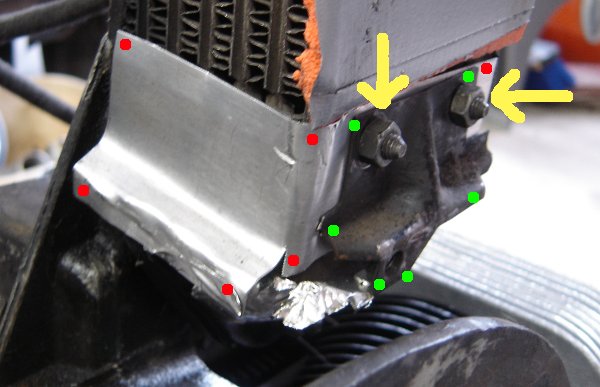

Here's a close-up of the base of the oil cooler.

The green dots mark the edges of a piece of sheet metal that's

sometimes known as "the Hoover bit". It provides a place for the fan

shroud to bolt to, and forms an air dam to keep air going around the

oil cooler. My hoover bit is broken, there's an arm missing that's

supposed to wrap around to the left side as seen in this picture.

I've replaced that functionality with a piece of sheet Aluminum that I

bent to shape, which is marked with red dots. Both the original

hoover bit and my sheet Aluminum patch are held on by the nuts

indicated by the yellow arrows.

When I got to think about removing the oil cooler to test it, those

nuts were the first things I took off. They were barely tightened on

at all. When I last assembled the engine, I must have thought that

their only job was holding on those two pieces of sheet metal. What I

didn't realize is those nuts are also two of the three fasteners that

hold the oil cooler on to the engine! The ends of those threaded

studs aren't part of the oil cooler, they are attached to the engine

and those nuts also hold the oil cooler itself in place. Here's the

oil cooler pulled most of the way off:

So basically my problem was that the bolts that provide the tension to keep the oil cooler sealed against the engine weren't torqued properly at all, and so oil was seeping out of the joint. Which is excellent news. So I cleaned up the sealing surfaces, put new seals in the space, put the oil cooler back on, and this time torqued it properly. I'm hoping that will resolve the issue.

One night this week I got back to putting on sheet metal and

assembling things. I got the inner sheet metal shrouding and the

crank pulley on. Here's when things stand now:

Next is the intake manifold and the fan shroud and generator.