I've been working for a couple of weeks on getting electronic ignition set up in my vintage Beetle. I bought one setup, which turned out to be badly made and really wasn't going to work. That's another story. The story for now is that Monday I bought a Pertronix electronic ignition module from vwparts.net on Monday, it arrived yesterday mid-afternoon, and about sundown the engine was running successfully.

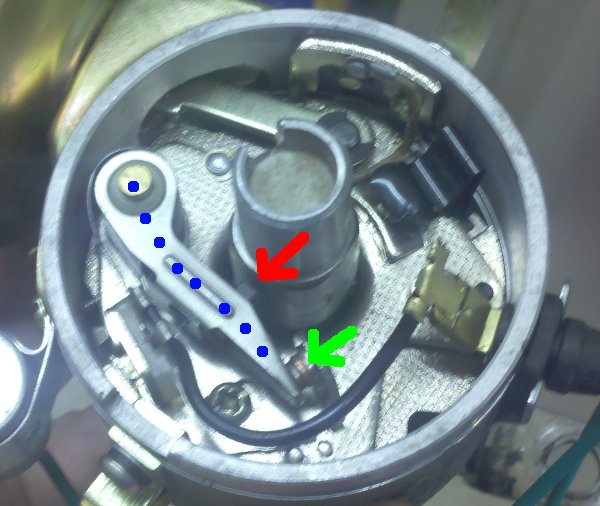

Here's what the inside of a classic VW distributor

from the factory, with old-style "points" installed:

The shaft in the center of the picture rotates when the engine

rotates. The shaft isn't round; as the shaft rotates,

the lobes of the shaft push against the rubbing block (red arrow),

moving the points arm (marked with blue dots) and opening

(disconnecting) the contacts (green arrow). Then the lobe passes and

the arm closes the contacts again. When the contacts are closed the

black wire is electrically conneced to the distributor body; when

they're open it isn't.

The reason for doing this is complicated, but the important thing is that something inside the distributor closes a switch and opens a switch in response to the rotating of the engine. This points setup is a simple way of accomplishing that goal. The problems with it are that there are several points of mechanical wear. The points degrade from the constant sparking and need to be replaced. The timing of the engine drifts as that wear happens. Eventually, the bearings of the distributor shaft wear out because of the constant pushing from the rubbing block.

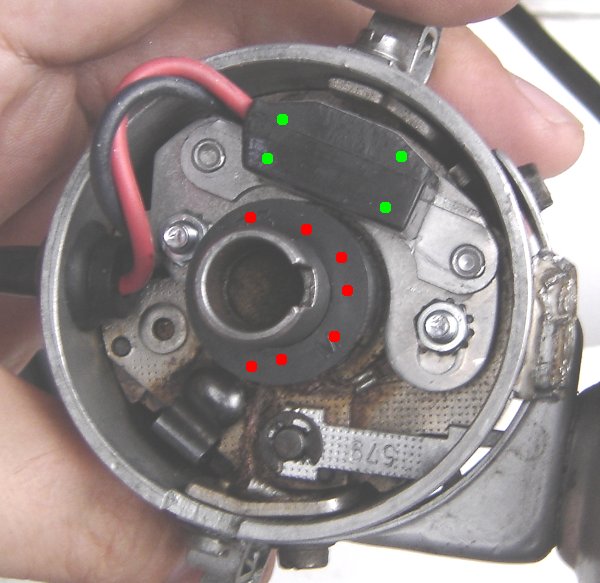

The inside of the distributor in the car now looks like this:

The black ring marked with red dots fits down over the shaft and locks

onto it, so that it always rotates with the shaft. It has 4 magnets

in its rim. The black box marked with green dots contains a magnetic

sensor and the other electronics. As the black ring rotates, it

senses the small magnets going by, and in response, it electronically

connects and disconnects the black wire to the distributor body,

just like the points did.

The advantages of this approach are:

One additional consideration; the points worked by using a mechanical

switch to connect the black wire to the distributor, and the movement

of the switch (the points) was provided by the rotation of the motor.

With the electronic system, the electricity has to be delivered to the

electronic module to power it. So instead of one wire coming out of

the distributor, there are now two.

The black one goes to negative

side of the coil just like in the points setup. The red wire goes to

the positive side of the coil (which is hot when the key is on) and

powers the electronic ignition module. I've put a fuse in the

positive line, just in case something inside the distributor touches,

it won't burn up the wiring.